We are proud to provide comprehensive inspection, repair, heat treatment and storage solutions for some of the leading pallet pools in the world. We are committed to providing quality and service excellence.

By repairing pallets ready for reuse, we are contributing to a circular economy model and helping to ensure a sustainable supply chain solution. Reuse reduces waste, lowers cost and has a positive impact on carbon emissions.

Inspection

When we receive a new batch of pallets into one of our depots, the first stage is inspection. We check each pallet for noticeable wear and tear and ensure the integrity of the unit. At this point a decision is made as to whether it requires repair or whether it is already delivery-ready.

Repair

Pallets need to be robust to survive the rigours of logistics. Almost half of the pallets that come into our depots require some element of repair, to ensure they are at the highest quality before they return to the supply chain. Any repair work will then require repainting and often heat treatment.

Heat treatment

Without the appropriate heat treatment, the pallets we process would not be able to leave the UK. We heat treat the pallets to the requirements laid down within the ISPM 15 international standard.

Storage solutions

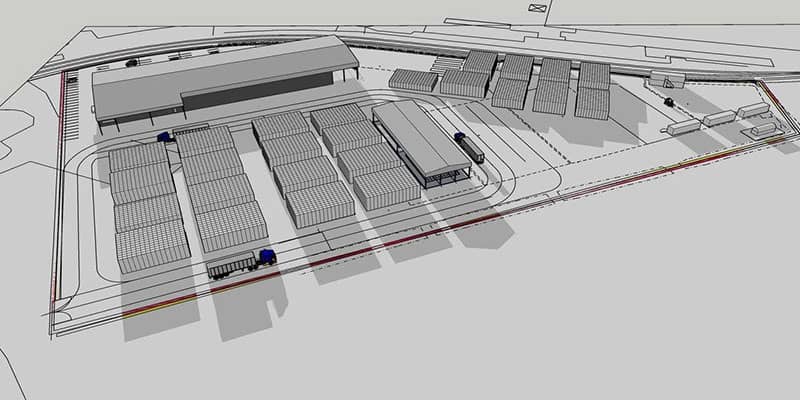

Our depots are designed to provide efficient storage solutions for the pallets once they have been inspected, repaired and treated, ready for their next journey.